Inviterte

foredrag til 8. Norske Polymer- og kolloidvitenskapelige

Vårmøte

Novel

Amphiphilic Block Copolymers

Made

by Controlled Free Radical Polymerization

André

Laschewsky

Universität

Potsdam, Institut für Chemie Karl-Liebknecht Str.24-25, 14476

Potsdam-Golm

laschews@rz.uni-potsdam.de

and

Fraunhofer Institut für Angewandte Polymerforschung FhG-IAP ,

Geiselbergstr.69, 14476 Potsdam-Golm (Germany),

laschewsky@iap.fraunhofer.de

Amphiphilic block copolymers

are a

most intriguing species of amphiphiles.1-6 However, the preparation of

such

block copolymers had been considered for long to be the "holy grail"

of polymer synthesis, as generally, delicate living polymerization

methods had been

necessary. These methods are mostly cumbersome, very sensitive against

impurities, and have only low tolerance to functional groups, in

particular to

such that are hydrophilic, consequently limiting the synthesis of

amphiphilic

block copolymers to few systems. This situation changed dramatically

with the

advent of the methods of controlled free radical polymerization (CFRP)

since

2000,7-9 which are much more tolerant

of

functional groups. This created a booming research field in the past

decade,

and has made numerous polymers with so far unusual - or even unknown -

block

structure and of unusual architecture accessible.3, 4

This contribution will first

introduce to the strategies, opportunities and difficulties encountered

in the

synthesis of amphiphilic block copolymers by CRP, in particular by the

RAFT

(reversible addition fragmentation chain transfer) method. Then, the

making of

classical polymer architectures will be addressed. Finally, unusually

complex

block copolymer amphiphiles made accessible by virtue of this technique

will be

exemplified, highlighting amphiphilic stimulus-sensitive systems,

triphilic

ternary block copolymers, and dual brush giant surfactants.10-16

|

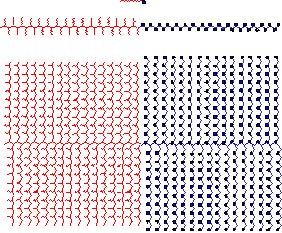

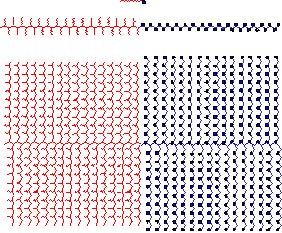

Scheme 1. Comparison of

the

architecture of a standard surfactant, a macrosurfactant, and a giant

surfactant (from top to bottom). The left (~~~)

and the right side (·) represent the

hydrophobic and hydrophilic

elements, respectively.

|

References

- I. W. Hamley, Block

Copolymers in Solution: Fundamentals

and Applications. John Wiley & Sons Ltd: Chichester,

England, 2005.

- S.

Garnier; A. Laschewsky; J. Storsberg, Tenside

Surf. Det. 2006, 43,

88-102.

- J.-F. Lutz, Polym.

Int. 2006, 55,

979-993.

- A. Blanazs; S. P. Armes; A. J. Ryan, Macromol. Rapid Commun. 2009, 30,

267-277.

- M. A. Cohen Stuart, Colloid

Polym. Sci. 2008, 286,

855–864.

- I. C. Reynhout; J. J. L. M.

Cornelissen; R. J. M. Nolte, Acc. Chem.

Res. 2009, 42, 681-692.

- K. Matyjaszewski; T. P. Davis, Handbook of Radical Polymerization. John

Wiley and Sons, Inc.: Hoboken, 2002.

- K. Matyjaszewski; ed., Macromolecular

Engineering: Precise

Synthesis, Materials Properties, Applications. Wiley-VCH:

Weinheim, 2007; Vol. 1.

- V. Percec; ed., Chem.

Rev., vol.109 (11), thematic issue

on: Frontiers in Polymer Synthesis 2009.

- M. Arotçaréna;

B. Heise; S. Ishaya; A. Laschewsky, J. Am.

Chem. Soc. 2002, 124,

3787-3793.

- K. Skrabania; J. Kristen; A.

Laschewsky;

Ö. Akdemir; A. Hoth; J.-F. Lutz, Langmuir

2007, 23, 84-93.

- M. Mertoglu; S. Garnier; A.

Laschewsky;

K. Skrabania; J. Storsberg, Polymer 2005, 46, 7726-7740.

- K. Skrabania; H. v. Berlepsch; C.

Böttcher; A. Laschewsky, Macromolecules

2010, 43, 271-281.

- A. Laschewsky; J.-N. Marsat; K.

Skrabania; H. v. Berlepsch; C. Böttcher, Macromol.

Chem. Phys. 2010, 211,

215-221.

- D. Zehm; A. Laschewsky; M.

Gradzielski;

S. Prévost; H. Liang; J. P. Rabe; R. Schweins; J. Gummel, Langmuir 2010,

26, in

press (doi: 10.1021/la903087p).

- A. M. Bivigou-Koumba; E.

Görnitz; A.

Laschewsky; P. Müller-Buschbaum; C. M. Papadakis, Colloid Polym. Sci. 2010,

288, online first.

Preparation of non-spherical composite

nanoparticles

Alex M. van

Herk, Hans Heuts, Syed Imran Ali

Eindhoven University of Technology, The Netherlands

Colloidal nanocomposites are of major

interest to improve properties of polymeric films. Many projects focus

on incorporation of clay platelets in latex systems. Only few systems

actually succeed in encapsulation of clay platelets. In order to use

the full potential of incorporation of clay in latex particles the

orientation of the clay platelets in the final film should be

non-random. This means that the anisotropy of the clay platelet should

be expressed also in the shape of the latex particle. So peanut shaped

and flat latex particles are desired structures that in principle could

lead to maximum usage of the high aspect ratio of the clay platelets.

In this presentation the results of successful encapsulation of both

natural and synthetic clay is shown, leading to anomalous latex

particle shapes that can be used to make polymeric films with desired

alignment of the clay platelets.

Modification of the clay in combination with a designed emulsion

polymerization process is the key to obtaining the desired results.

Growing polymer from the surface by a RAFT approach can lead to uniform

layer thickness of the encapsulating polymer and therefore to flat

latex particles.

|

|

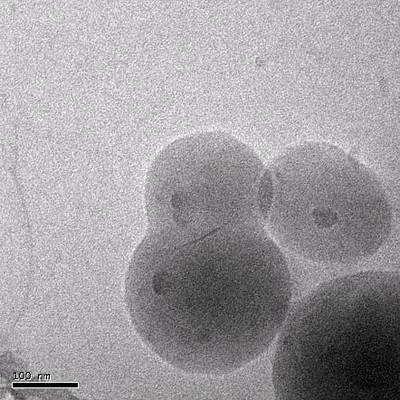

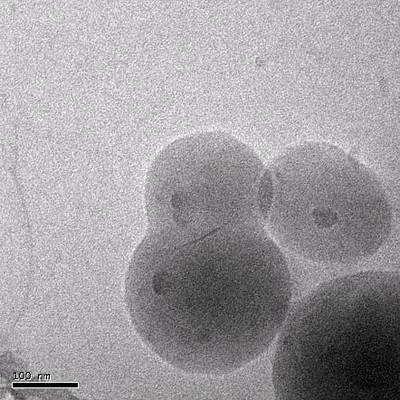

| Dumbell

or peanut shaped latex particles obtained in a conventional starved

emulsion polymerization in the presence of modified montmorrilonite

clay platelets [1]. |

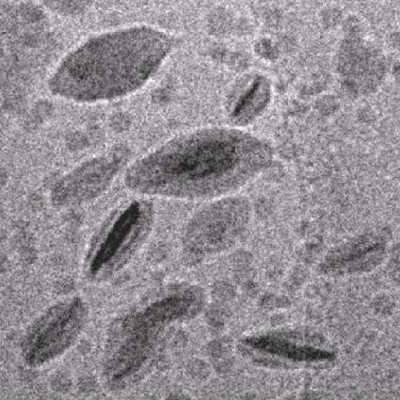

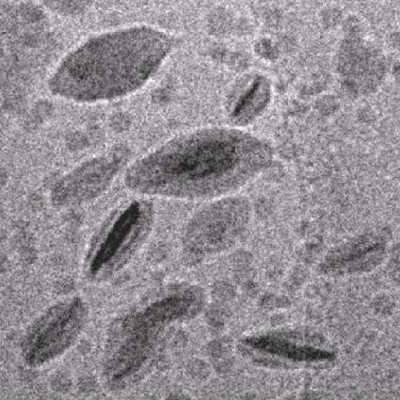

Flat

latex particles obtained in a RAFT controlled emulsion polymerization

onto synthetic Gibbsite clay platelets [3]. |

References:

- D.J. Voorn,

W. Ming, A.M. van Herk, Macromolecules 2006, 39, 4654-4656

- A.M. van Herk and A.L. German, "Microencapsulated pigments

and

fillers", contribution to the book 'Microspheres, Microcapsules

&

Liposomes', vol 1 : Preparation & Chemical Applications, Citus

Books, London , ed Prof. R Arshady (1999).

- S.I. Ali, J.P.A. Heuts, B.S. Hawkett, A.M. van Herk,

Langmuir 2009, doi:101021/1a9012697

Siden oppdatert 29.1.2010